- Login or Register

No account yet? Sign up

Why is it a good news ?toraabe wrote: ↑21 Apr 2022, 12:44What I expected. Good news. https://www.planetf1.com/news/max-verst ... -new-cars/

It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.TNTHead wrote: ↑21 Apr 2022, 12:18I would suggest it seems mainly engine related vibrations, may be leading to fatigue at the connection points. I wonder whether the combustion characteristics due to E10 has lead to increased vibration levels on the high pressure pump and/or block. If not one would assume it would be a consequence of the packaging layout.Big Tea wrote: ↑21 Apr 2022, 11:28TBH, I was thinking of engine or pump generated vibration rather than proposing, which would be very long wave.ringo wrote: ↑21 Apr 2022, 01:16

Yes, but for resonance the frequency has to match the natural frequency of the arrangement; correct me if I wrong.

The car is bouncing no more than 5 Hz.

check this link for some equations : https://www.engineeringtoolbox.com/stru ... _1989.html

Say I use the Structure with Fixed Ends and Distributed Mass model, with a 20kg/m load; which we know is not the case. f = 3.56 (E I / q L4)0.5

L may be as much as 0.5 metres. Say the pipe is 10mm OD and 9mm ID. I get a frequency of 74Hz for example.

The lesser the external load the higher the frequency will be.

It's more complex than I am making it out here but its just an idea of the scale of things and how far the porpoising frequency is from a possible resonance issues. Then you must ask, what is the damage mechanism from the resonance?

Will fatigue failure arrive so quickly?

As you say the whole thing is complex and inter related. As they seem to struggle for weight even adding a few more fixing points would have to be studied and balanced weight v possible problem. I think just sit back and see what they find.

Supposedly press mentioned the power unit was shipped back to Honda. It might be a fluke of their specific arrangement of plumbing this season. Thinking of the high pressure lines: what shock absorbing features do they use between the pump and the injectors?matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.

They may use the damping properties of rubber fixtures or of the pipes themselves. I do not think they have specific shock absorbers.vorticism wrote: ↑21 Apr 2022, 16:15Supposedly press mentioned the power unit was shipped back to Honda. It might be a fluke of their specific arrangement of plumbing this season. Thinking of the high pressure lines: what shock absorbing features do they use between the pump and the injectors?matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.

Yes it was a very rough calculation. The point of it was to show generally that a steel tube excited by a low damped frequency it is unlikely that there will be resonance. I am not expert, I've only done some vibration theory years ago in undergrad.matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.TNTHead wrote: ↑21 Apr 2022, 12:18I would suggest it seems mainly engine related vibrations, may be leading to fatigue at the connection points. I wonder whether the combustion characteristics due to E10 has lead to increased vibration levels on the high pressure pump and/or block. If not one would assume it would be a consequence of the packaging layout.Big Tea wrote: ↑21 Apr 2022, 11:28

TBH, I was thinking of engine or pump generated vibration rather than proposing, which would be very long wave.

As you say the whole thing is complex and inter related. As they seem to struggle for weight even adding a few more fixing points would have to be studied and balanced weight v possible problem. I think just sit back and see what they find.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.

Now that you say this, another failure mode could be "hammering". If the fuel is flowing the the pipe and comes to an abrupt stop a shockwave will bound off the closed end and back upstream towards the check valve in the line. When the check valve closes the kinetic energy of the wave will turn to pressure energy and induce a pressure spike. And what happens here is the couplings will just fail as the pressure spike would go beyond the pressure rating of the coupling. Additionally if the tubes were designed to exact, they could also be damaged from the pressure spike.vorticism wrote: ↑21 Apr 2022, 16:15Supposedly press mentioned the power unit was shipped back to Honda. It might be a fluke of their specific arrangement of plumbing this season. Thinking of the high pressure lines: what shock absorbing features do they use between the pump and the injectors?matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.

I am not thinking about the pipe breaking directly because of vibration; I am thinking about the pipe resonating and breaking/loosening at the connections. Also we keep thinking about the pipe as a fixed-fixed beam, but if the connections at the two ends are, e.g., rubber, it is more like a free-free beam suspended by means of two relatively soft springs. If that is the case the first 6 rigid body modes of the free-free beam would be "replaced" by the 6 modes dictated by the connections, which can easily be an order of magnitude lower than the first bending frequency of the beam itself.ringo wrote: ↑21 Apr 2022, 18:30Yes it was a very rough calculation. The point of it was to show generally that a steel tube excited by a low damped frequency it is unlikely that there will be resonance. I am not expert, I've only done some vibration theory years ago in undergrad.matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.TNTHead wrote: ↑21 Apr 2022, 12:18

I would suggest it seems mainly engine related vibrations, may be leading to fatigue at the connection points. I wonder whether the combustion characteristics due to E10 has lead to increased vibration levels on the high pressure pump and/or block. If not one would assume it would be a consequence of the packaging layout.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.

And you are right, it's hard to predict. But let's say this fuel pipe does resonate.. would the metal thin then tear?

The steel tube would probably balloon and thin before it bursts. This is not likely.

I do know that copper tubes do not deal well with vibration well and can break, but copper is a different kind of material.

I hope the team sheds light on what really happened. Or we ask Scarbs to do some digging.

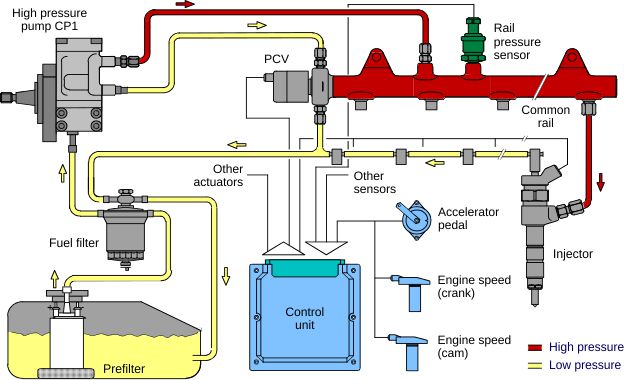

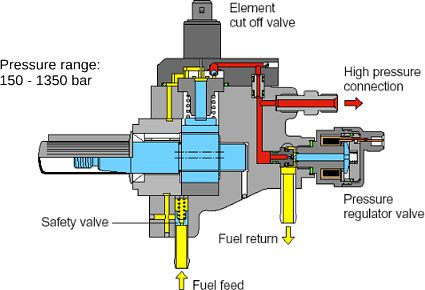

Not sure what's standard practice for these specific gasoline DI systems; maybe some gas or mechanical spring shock absorber is present. As it relates pressure relief valves feeding a return line may be the primary safety. f.e. common rail schematic with a pressure control valve pictured below although I'm not sure if there's a redundant mechanical relief as a backupmatteosc wrote: ↑21 Apr 2022, 16:32They may use the damping properties of rubber fixtures or of the pipes themselves. I do not think they have specific shock absorbers.vorticism wrote: ↑21 Apr 2022, 16:15Supposedly press mentioned the power unit was shipped back to Honda. It might be a fluke of their specific arrangement of plumbing this season. Thinking of the high pressure lines: what shock absorbing features do they use between the pump and the injectors?matteosc wrote: ↑21 Apr 2022, 15:21It could be vibration from any source and not necessarily porpoising, but do not trust that "74 Hz" number: without knowing exactly geometry and material you cannot possibly guess it right.

I do have some experience in the field (PhD in vibrations and multibody dynamics, working on the topic ever since) and I can tell you that you will always be surprised on how seemly unpredictable the interactions between all the structural components are.