If you put a balloon against your forehead, then let someone kick it. How far would your head kickback? Chances are the balloon distorts and your head doesn't move. Compare this to putting a bowling ball against your forehead. I know the bowling wont compress but your head will the the thing that moves.hardingfv32 wrote:Why are you talking about bodies? Is the body from the floor section up? The RB has a separate floor assembly. Can it not bend without influencing the body? How could the body be affected?

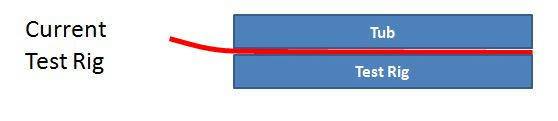

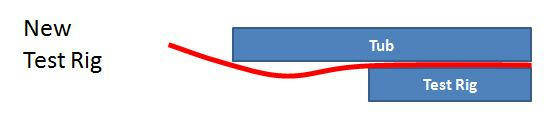

Can an interior section of the floor assembly bend without the perimeter of the floor assembly being effected, say 5-6mm?

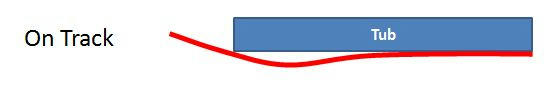

To be very precise, we are only concern about the movement of the plank as the is the only part check for wear.

I do not understand your concerns. Can you clarify?

Brian

The difference is between the stiffness of the bowling ball and the balloon.

It doesn't matter if you are only interested in one part of the system. The external forces have to be understood and resolved before you move on to the internal stuff.

So for a rough example if the car weighs 6400N and has about 12800N of downforce, a total weight of 19.2 kN over the axles at an instant, as the splitter contacts the ground it will be supporting a fraction of this weight, let's say less than a third, as the wheels are supporting the rest.

The stiffness of the floor and the plank have to be at a level where this force can deflect it if it is that it must bend and be flush with the track. If it takes more than this reaction force to deflect the splitter, the whole car body will simply move as one piece and the splitter simply wont move.

The balloon and bowling ball analogy is a good reference of what i am getting at here. Pardon me if i can't make it clear enough.

So how weak do we need to make the splitter joint so that it can bend under say a third of the load on the axles.. 6.4kN from my example?