WhiteBlue wrote:The system that is likely to work with best efficiency would be a combination of an oversized exhaust gas turbine with a conventionally dimensioned charging compressor on one shaft. In addition the shaft would need to be connected to a power source/sink. During engine spool up the power source would kick in accelerating the compressor beyond the means of the turbine to build the compressor power without turbo lag. When the engine builds rpm and the turbine reaches the change over point and starts to deliver more power than the compressor needs the external power flow reverses. Power is now taken from the turbo shaft to prevent the compressor to over pressurize. Such a system does away with the need for a waste gate and anti lag engine mapping. It is capable of delivering additional compounded power in the order of 10-15% of the engine power. It is feasible for F1 because the engines run mostly on full throttle compared with road cars.

We have already discussed two relatively simple methods to achieve the reversing of the external power flow. Hybrid cars with electric high energy storage can use an electric servo MGU which is fast enough and only adds a few kg for the MGU and the inverter. With compound power of 40-60 kw the power/weight ratio is attractive. The battery capacity is available already.

If the car has no hybrid drive train you can achieve the same thing with a Torotrak CVT. It is equally capable of reversing the power flow from the engine crank shaft to the turbo shaft. The weight and efficiency quoted by Torotrak for such designs look quite feasible.

Putting the ICE and the turbo machines on the same shaft makes no sense IMO. The turbo shaft could be on one side of the engine as BMW did or it could be above the gear box or diff. I proposed that config already in the old thread and did a 2D power point graphic on it. The 3D design by ringo just makes it a bit easier to understand.

You are suggesting putting a motor/generator around the power shaft in between the turbine and compressor? This is actually a good Idea. I think it's being used already so that is definitely a possibility for 2013.

Electronically controlled anti lag is a good idea.

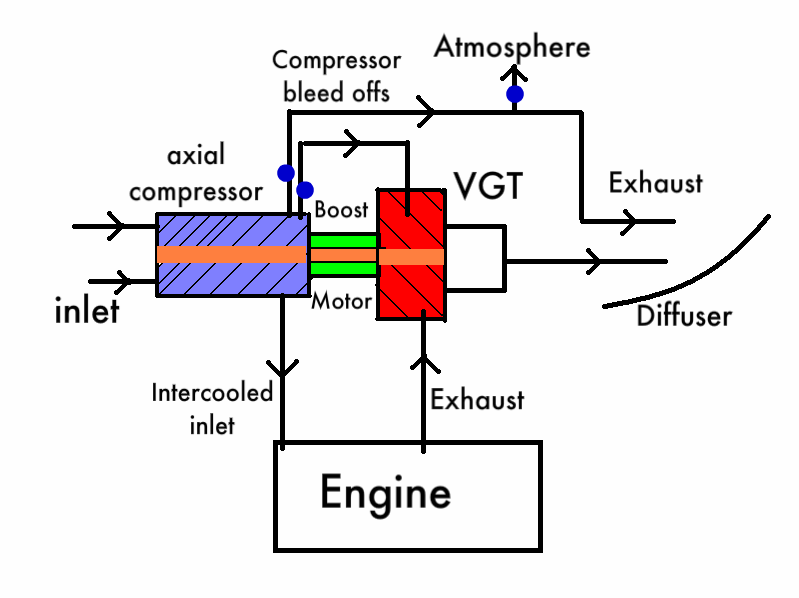

For auto-gyros Idea. If you want a have a compressor spining at one speed, and have the provisions to do it, then a axial compressor will be the best choice. High efficiencies but Extremely high pressure ratios though, and the stability range is very small. So you need to have that electronic motor pumping in energy through the turns and even a variable vane Turbine to keep the speed of the axial compressor up.

Then again Since the pressure ratio is so high, you can run the axial compressor at half capacity by just bleeding off excess boost back into the turbine, or over the diffuser. If this is electronically controlled you can keep a relatively constant boost level.