PlatinumZealot wrote: ↑03 Feb 2021, 18:30

godlameroso wrote: ↑01 Feb 2021, 17:00

Kumabo is not Honda. Kumabo metal company developed the material for Honda.

Again, you have the material for a few months 2020 is right around the corner. Do you go all out on a new experimental coating, push it to the limit? How can you in the middle of a pandemic lockdown? So you build a safety margin on previous data, and slowly turn it up.

2021 there's no pandemic lockdown, you've had a full year to test the material, how to work it, and push it to its limit.

Big difference, not to mention there was no in season update.

No engineer, or engine maker will use an

experimental coating on an engine that needs to last 3,000 km, I can tell you that. That is too great a risk to run an experiment in something like the Power unit where the penalty is severe. Any new material to be used in the race, is not really new, but tried and tested in all sorts of use cases.

If the dyno shows good numbers, but you have not ran it on track, how can you be sure it will work exactly on track as on the dyno? We remember 2017 don't we? The engine worked fine on the dyno, on track, not so much. So you leave safety margin to avoid any issues that comes from environmental differences. Since you cannot simulate actual environmental conditions you cannot calculate true on track wear.

Then actual on track running, which can only happen during the season showed Honda the material was safe to push. So much so, they were able to have very low wear on the final engine spec, it could likely have done another two races without losing performance. However once the season started it was too late and they could not introduce a more aggressive spec. They actually improved the engine from testing to the season opener, but did not improve as much as they could have with more time. Once the season started, their hands were essentially tied they could not change the spec of the engine.

Imagine now, you understand how far you can push the material, you've had a whole year to see how far you can bump up cylinder pressure. Would you push it to the absolute theoretical limit that will let you finish 7-8 races? Would you still leave yourself a safety margin?

Safety margin is very important for obvious strategic reasons.

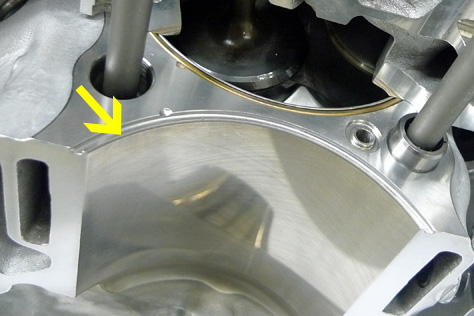

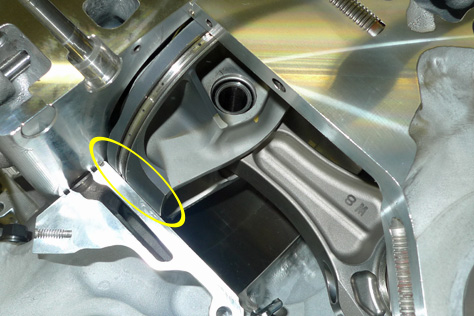

The difference between the final engine Honda used vs the 1st was the improved ring seal because they improved how to work the material. This gave them excellent longevity, they could push the engines hard with little wear, Gasly's engine demise was unfortunate. The fact they had such good reliability paid off for Red Bull at the end of the season, they could run the engine harder than Mercedes.