So here's what I'm wondering:wuzak wrote:They could offset the MGUH to lower the shaft, but then you have to gear the MGUH to the shaft which is, by all accounts, difficult to get right in the first place.

What clearance do you think there is between the top of the crank throws in the bottom end, and the lowest part of the turbine shaft that the compressor and turbine sit on?

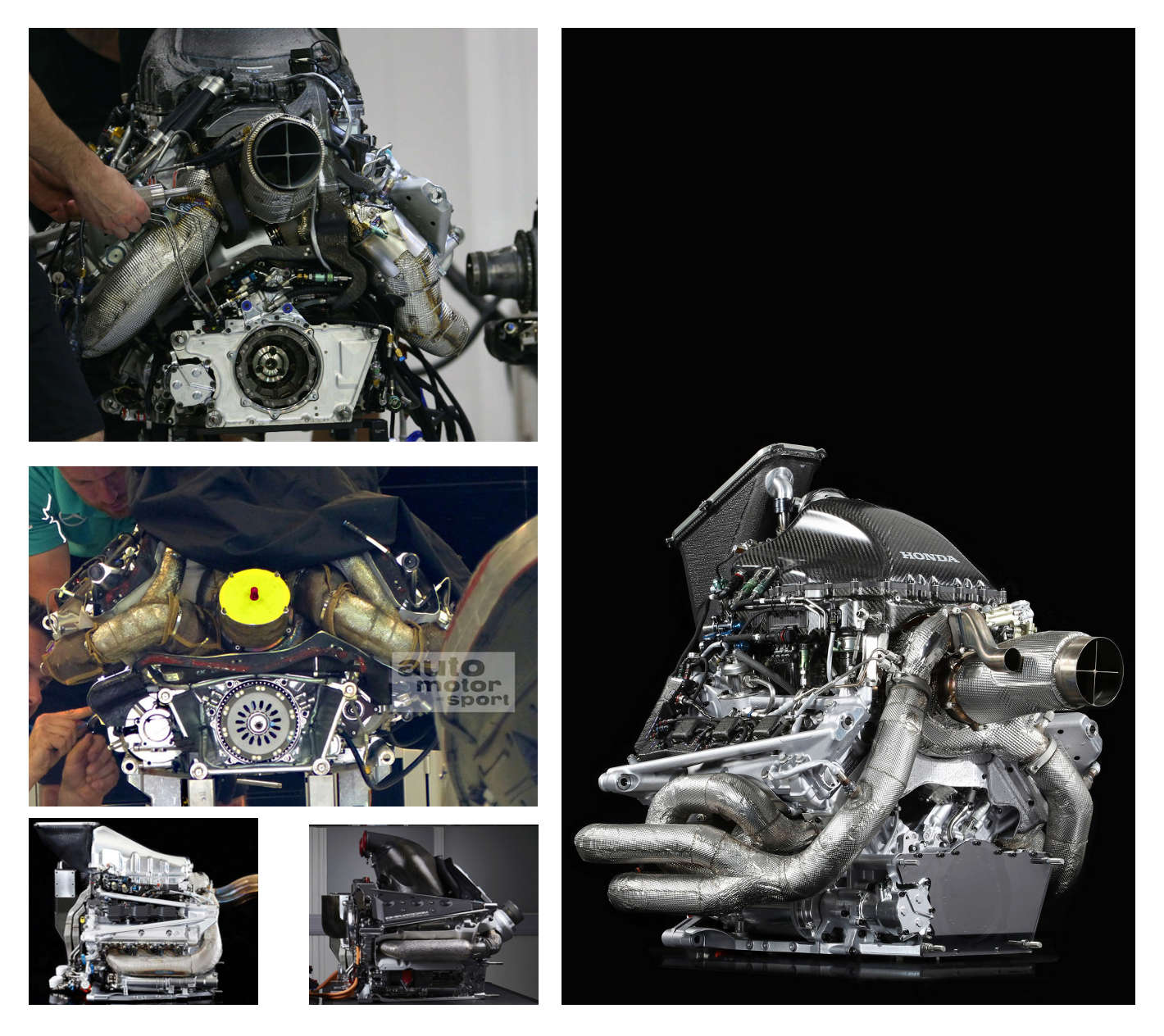

I'm wondering if the long shaft running from one end of the engine to the other might be inside the top part of the block, near to or below the bottoms of the cylinders.

The seals in such an arrangement would be horrible to engineer because the shaft rotates so quickly (limit is 125K rpm, assuming full speed permitted in the regs).

It'd also be a nightmare to package the MGU-H inside the vee of the engine. Not impossible.

The benefit is compactness, of course.

If the block was to distort (even by a little), then the shaft running the length of the engine would bind and smash up its bearings/seals.