holeindalip wrote: ↑16 Jul 2022, 23:06

godlameroso wrote: ↑15 Jul 2022, 22:25

Tommy Cookers wrote: ↑15 Jul 2022, 21:58

there is no (turbine) "backpressure to the combustion process"

exhaust is inherently a choked process - ie the backpressure has no effect on the power stroke

It does have an effect on cylinder scavenging and filling, which are crucial to the power stroke. As the power stroke is entirely dependent on those intermediate events, much like combustion itself is determined by intermediate reactive radicals in the fuel.

On a completely unrelated note, cooling exhaust gas could have the benefit of increasing the mass density of said gas. Afterall a limiting factor to a compressor is that the air is compressed to a point that the heat generated lowers density and with it the ability to do work. That is why intercoolers make more power, they increase the air density improving cylinder filling.

Perhaps one of the reasons fuel is necessary to power an engine is the fact that the density of combusted gases having CO2, NOx, and other molecules that are more dense than air means that you don't lose much gas density despite the high temperature. I imagine if we just heated air, it's density would be so low that there would be little to no power generated.

Are you saying cooler denser air in the hot side will drive the turbine more/better? I always thought you wanted it hot as the air expands driving it more efficiently, hence why everyone moved to wrapping everything on the hot side to put as much heat through there as possible….

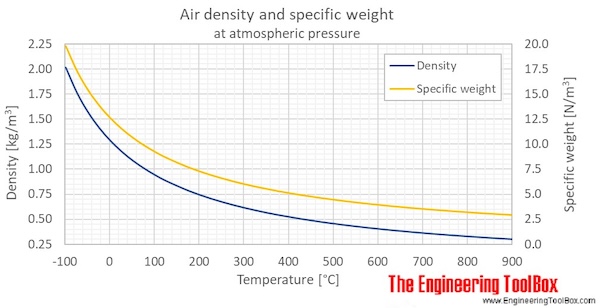

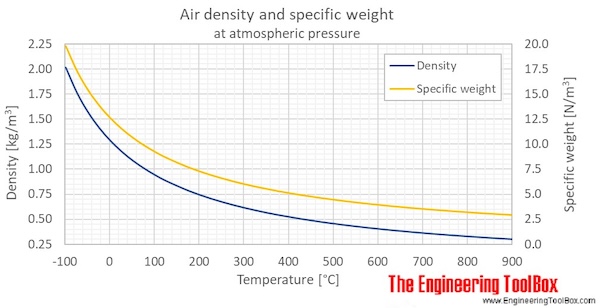

Depends, air density decreases greatly with temperature increase. The reason for wrapping the exhaust manifold, and exhaust, is because higher temperatures raises the Mach number, in other words, it extends the choking limit, because again lower density means less pressure rise, and hence lower back pressure. However then you get to a point where the exhaust geometry needs to be perfect to get the most power, even scratches or carbon build up can cost 3-4hp.

Air's density in particular is greatly affected by temperature. Combustion products have a density of ~1.1kg/m3 at a temperature of around 1,000C, whereas air has a density of ~.25kg/m3 at that temperature. At the temperature of combustion which is around 500-700c hotter, the relationship is even more lopsided. Particularly when you start producing NOx. In addition, the kinematic viscosity of air increases with temperature as well, so to an extent the density decrease is countered by the viscosity increase, although the relationship between all these variables are not linear so it makes it quite complex to study said relationship.

Cooler denser air flows easier, and has more momentum than a similar amount of much hotter air, however the increased density more easily creates a bottle neck and as a result increases system backpressure.

Remember Wazari-san said that turbine power and crank power are conflicting goals and finding the right compromise between the two is the big challenge with these power units.