- Login or Register

No account yet? Sign up

Looks vapor smoothed 3d printed filament to me. You can about see the ghosting of the layer lines near the rear tyre.PlatinumZealot wrote: ↑22 Oct 2022, 01:36Looks like black paint to me to hide the carbon layups. Perhaps the floor is designed to flex a ceratin way?

You should look into CF-PEKK and CF-PPSU.PlatinumZealot wrote: ↑22 Oct 2022, 02:37Sounds too weak for the job of a diffuser. Good amount of stiffness would be needed.

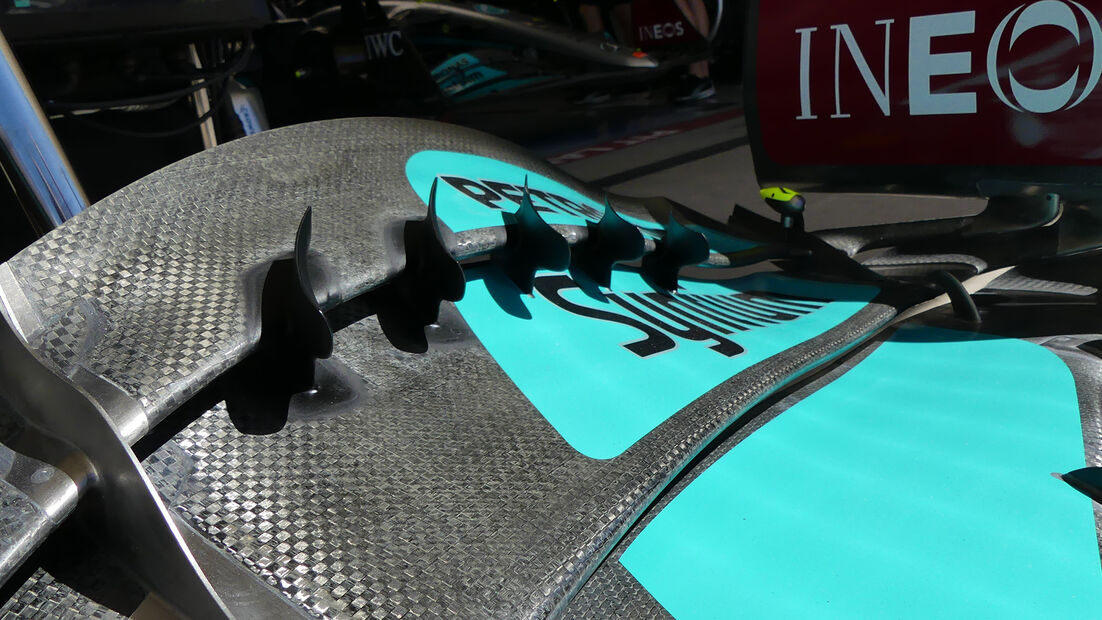

Seems like FIA is not happy with the size of 'Goblin'.pursue_one's wrote: ↑22 Oct 2022, 04:24Mercedes has to modify new front wing design(reduce the size og the slot gap separators) after FIA complaint

https://imgr1.auto-motor-und-sport.de/M ... 946103.jpg

https://www.auto-motor-und-sport.de/for ... uegel-fia/

Please tell me you aren't referring to that crap $1k/kg stuff that any decent enthusiasts printer can run.Zynerji wrote: ↑22 Oct 2022, 03:17You should look into CF-PEKK and CF-PPSU.PlatinumZealot wrote: ↑22 Oct 2022, 02:37Sounds too weak for the job of a diffuser. Good amount of stiffness would be needed.

They are almost interchangeable with aluminum.

Sure. There are amorphous and crystalline material filaments to fit the need. AM have been using printed steering wheels for years.dans79 wrote: ↑22 Oct 2022, 05:28Please tell me you aren't referring to that crap $1k/kg stuff that any decent enthusiasts printer can run.Zynerji wrote: ↑22 Oct 2022, 03:17You should look into CF-PEKK and CF-PPSU.PlatinumZealot wrote: ↑22 Oct 2022, 02:37Sounds too weak for the job of a diffuser. Good amount of stiffness would be needed.

They are almost interchangeable with aluminum.

It's a chopped carbon fibre filament. I have seen these 3d printed Chopped fibre tested on youtube. it has to be very finely choped to be printed out the nozzle so you can imagine much directional strength is lost. It's has to be finished by hand too to get it looking nice when done. It doesn't come out as nice as the diffuser image you see there.Zynerji wrote: ↑22 Oct 2022, 03:17You should look into CF-PEKK and CF-PPSU.PlatinumZealot wrote: ↑22 Oct 2022, 02:37Sounds too weak for the job of a diffuser. Good amount of stiffness would be needed.

They are almost interchangeable with aluminum.

You should look a bit deeper. CF-PEKK is FAA approved for finished parts in airplanes and helicopters. And the surface finish can be chemical vapor "smoothed", creating a continuous outer shell. It could, very easily, work as a load bearing part. I see no reason why it couldn't work as an air duct.PlatinumZealot wrote: ↑22 Oct 2022, 11:40It's a chopped carbon fibre filament. I have seen these 3d printed Chopped fibre tested on youtube. it has to be very finely choped to be printed out the nozzle so you can imagine much directional strength is lost. It's has to be finished by hand too to get it looking nice when done. It doesn't come out as nice as the diffuser image you see there.Zynerji wrote: ↑22 Oct 2022, 03:17You should look into CF-PEKK and CF-PPSU.PlatinumZealot wrote: ↑22 Oct 2022, 02:37Sounds too weak for the job of a diffuser. Good amount of stiffness would be needed.

They are almost interchangeable with aluminum.

In fact it might even be better to print that part out of metal if you just need to test a new shape.

PlatinumZealot wrote: ↑22 Oct 2022, 14:23Post a photo or better yet videos of it being used in making something and of the vapour smoothing process and you will see.

Btw it's an alternative to PEEK so that sorta tells you how it is.

doing your work for you.

https://youtu.be/PV5luJxosOo

Better to end the speculation. Now we can concentrate on the new Front wing, and it's legality!PlatinumZealot wrote: ↑22 Oct 2022, 14:43It's just a cover as he says. It can be anything. Someone further up in the posts thought it was part of the diffuser itself. I was arguing rrom the point of the diffuser (the area behind that cover). So this whole coversation is moot.