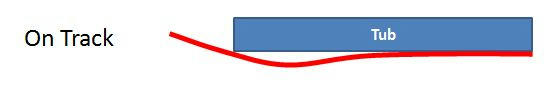

1) "The large hole in the floor is for the tub. Why waste 5 mm of height on a floor when the tub can be lowered by 5 mm?"

Weak statement. Why does RB have a floor assembly? Using your logic we should see everything mount to the tub/chassis.

2) "The fasteners have to be visible from underneath" Your point?

3) "secondly the floor can be in 3 sections, the shortest being 1m long." Yes it can, but in the case of RB it looks like a one piece unit which is not impediment to this system.

4) "3.12.5 All parts lying on the reference and step planes...."

A) As this is found in the "Bodywork facing the ground" section. I would argue that the Skid block is not covered by this rule.

B) This statement clearly is discussing parts the "on" the reference plain. I would argue that this means above, not below.

"3.15 Aerodynamic influence.... must remain immobile in relation to the sprung part of the car."

A) Here I would argue that the splitter based on how it is currently tested is understood to be mobile when it hits a big enough track irregularity.

B) The movement of the plank has no aerodynamic influence. It influences the wear of the plank.

5) "Another thing to consider is hamilton's broken floor in australia GP."

What about it? Do we know if McLaren uses a "see saw" plank system?

Brian

- Login or Register

No account yet? Sign up