I'm obviously not seeing what you're seeing as there's some very strange wear patterns there. Leading edge wear *could* be from the crash - i.e. going through the gravel taking that paint off. Or it could be normal for this car. Or it could be mud.ringo wrote:Ok good, and i am now seeing the fasteners which must be visble.

In fact there are 7 fasteners around the the black part and 4 spaced widely at the front.

The is wear pattern is the inverse of this:

The same idea but with the tip pointing down so that the middle part stays clean.

The tip pointing down is opposite to what the see saw is trying to achieve.

What is also intereing here is tha the plank is not weared evenly. It's really just a bunch of streaks, made to look like the whole surface is worn.

I can actually see that the tip has more excessive wear than the other scrubbed parts. I am referring to around the most forward hole. Look how evenly scrubbed it is. The area aft of this hole is in fact quite clean.

So i would say this floor is behaving normally, except for the clean patch in front of the 2 big holes. And this could be purely because of the tolerance in the manufacturing of the plank.

What I find really strange is the wear pattern before those two big holes where you have the darker band on the plank. You've got the highest level of wear on the entire plank just in front and behind that dark patch which indicates the lowest wear on the plank. You've also got streaks that run around the outside of that dark patch suggesting that it's not simply deformation of the plank. This dark patch was also on the shots of Webbers car when it flipped at Valencia.

Where exactly on this plank would the samples be taken from? Are we seeing Red Bull using different materials, as they do at the rear, or some kind of protective paint in that section? Why is wear at the front of the plank, up until the dark patch, pretty much uniform which suggests that it is parallel to the track rather than raked?

From those two holes backwards the plank looks effectively unworn showing that rake is keeping that part of the plank clear in the air.

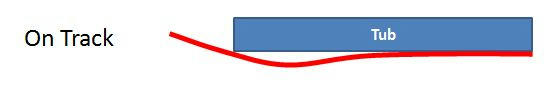

Forgive the really crude diagram, but I've tried to draw what I'm seeing in terms of the level of wear and what I'd expect to see. I've discounted the leading edge wear on the 'vertical' section simply because I think that this is not consistent across the whole edge, and I think it may actually be mud looking at how it smeared over the bolts at the front.

The blue line is what I'd expect if the plank were rigid and the car was raked. The red line is what I'm seeing as the wear on the plank on the Red Bull car. This is not to any sort of scale, just a relative indication for illustrative purposes.