Hello Riff-Raff

You write:

“If you read the text of the patent it describes the engine operating in both stoichiometric and stratified charge conditions.”

In the claims of Honda’s patent application there is nothing about stoichiometric or stratified combustion.

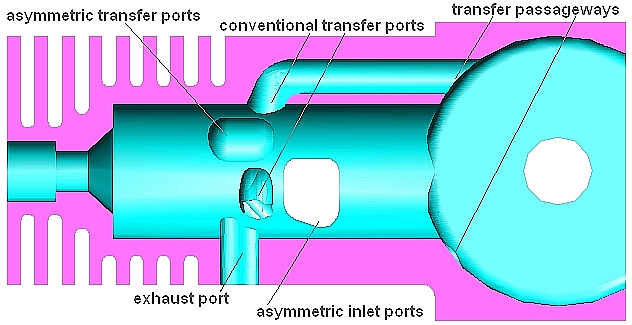

The specific patent application relates only with the arrangement of the transfer ports, of the piston, of the cylinder wall, of the injector and of the kinematic mechanism.

In the prior art they are described several fuel-injected two-strokes operating in both: stoichiometric and stratified lean combustion.

You also write:

“The engine described in that Honda patent is obviously intended as a single cylinder engine running at low rpm. It's a long stroke, small bore configuration. And the significant mass of the crank rocker arm mechanism would not lend itself to high speed operation.”

The kinematic mechanism achieves the reduction of the thrust loads (friction) between the cylinder liner and the piston skirt (how? by reducing the angle the main connecting rod tilts about the cylinder axis) in expense of additional bearings, heavier parts, complication, vibrations(?), cost etc.

Can this low-revving (due to the exhaust poppet valve and to the heavy moving parts) 2-stroke engine compete a 4-stroke Honda of similar capacity (and weight, and cost) running at double revs?

In the PatTwo Harmonic engine below (more details at

http://www.pattakon.com/pattakonPatTwo.htm )

the thrust loads between the piston skirt and the cylinder liner are minimized (they are several times lower than in the Honda 2stroke).

Besides being rid of reed valve(s), the PatTwo Harmonic engine is perfectly balanced (zero inertia forces, zero inertia torques, zero inertia moments).

Compare the basic kinematic mechanism of the Harmonic PatTwo:

with that of the Honda 2-stroke.

The most interesting is the load control it uses and the minimization of the pumping loss at light loads:

the engine idles (and operates at light / partial load) with the throttle valve (the dark part with the yellow lever at the middle) fully opened,

with the throttle valve progressively closing, the engine runs at higher revs and heavier loads,

with the throttle valve completely closed the engine provides at high rpm a lot of power,

and when the revs get adequately high, the wide opening of the throttle valve gives (in cooperation with a tuned exhaust, if any) full power.

It is not easy to be understood, but it is quite interesting (way more, I think, than a low-revving small 2-stroke that combines the disadvantages of the two and four stroke "schools"; let me wonder how many articles would be written about the "new" Honda 2-stroke if from the first page of the patent application the "Applicant: Honda Motor Co., LTD" and the Assignee: Honda Motor Co., LTD" were absent ).

Thanks

Manolis Pattakos