Hello J.A.W.

You write:

“Well Manolis, that sleeve valve 2T does look a bit like Uniflow's made in metal unit, way back on page 5 of this thread..”

The sleeve valve of R-R Crecy:

and the sleeve valve of Uniflow:

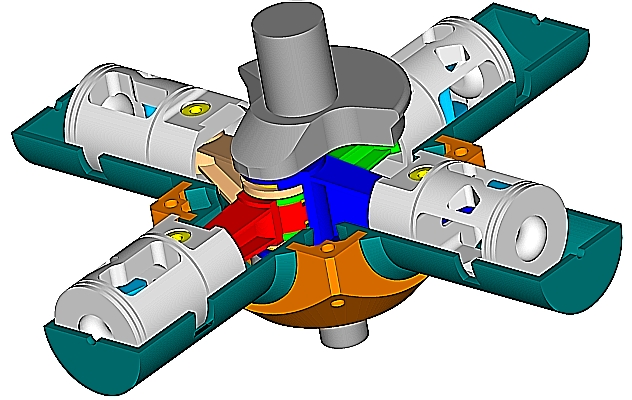

have, both, a substantial difference as compared to the present sleeve valve:

The top end of the R-R / Uniflow sleeve valves remain permanently into the combustion chamber, making inevitable the location of the exhaust ports substantially lower in the cylinder and closer to the transfer ports.

This, in turn, makes easy the “short-circuit” of the transfer and exhaust ports (unless the piston stroke is a couple of times longer than the bore) and increases substantially the quantity of the residual gas worsening the combustion and overheating everything.

In comparison, the exhaust ports of the present sleeve valve arrangement, shown in the stereoscopic animation, are at the top end of the cylinder, away from the transfer ports. The residual gas decreases. The top end of the sleeve valve exits from the cylinder and is cooled. The shape of the combustion chamber remains the same of the 4-stroke Pennine, Vulture, Centaurus, Hercules etc.

You also write:

“The Sabre was intended to be capable of running as a 2T, but even running 1/2 time as a 4T, the best available prop's of the day - were at their limits coping with its power outputs.”

With the Sambre running as a 2-stroke and the power almost doubled at the same revs (note: the valve time area doubles in comparison to the 4-stroke sleeve valve version because all the top periphery of the sleeve is covered with exhaust ports, and all the bottom periphery of the sleeve valve is covered with transfer ports), the problem of the propellers of those days was an easy one.

All it takes is to eliminate / to throw away half of the cylinders of the engine (say the top 12-cylinder boxer of the "H") and so almost half of the engine weight, resulting in more lightweight airplanes and cheaper / easier to make airplanes.

You also write:

“& as for wear/oil consumption, it was noted that the relative motion between sleeve & piston actually reduced these things, by comparison to more conventional aero-engines.”

The wear yes (3,000 hours TBO in the Bristol Sleeve Valve Radials), but the specific lube consumption?

The sleeve valve architecture provides several ways to the lubricant to get burned or be lost.

If you had to design a modern sleeve valve engine, how could you control the lubricant? (and the emissions caused by the increased quantity of lubricant into the combustion chamber)

By the way, less wear does not mean less friction.

You also write:

“I guess a frictional drag/wear/heat analysis would be a meaningful comparative for your interesting latest design.”

Correct.

The Sleeve Valve engines (maybe the best 4-stroke engines in their time) were used as a reference point in order to explain the several advantages of the PatOP Opposed Piston engine.

If you follow the progressive transition from the Sleeve Valve 4-stroke engine to the PatOP engine, you understand that without introducing significant side effects, several things are substantially improved.

Worth to mention:

Besides the previously mentioned advantages, the PatOP architecture transfers the thrust loads away from the hot region of the cylinder liner, away from the cylinder ports / openings, which is a significant change allowing 4-stroke-like lubrication.

With the PatOP / OPRE pulling-rod-architecture it is provided some 30% longer piston dwell at the combustion TDC: the piston remains at the top 10% of its stroke for some 30% additional absolute time, allowing more efficient combustion at the same revs, allowing also Diesel / compression-ignition engines providing substantially more power.

The revs of the peak power go from the, say, 4,500rpm of the present conventional push-rod automotive Diesel engines to 6,000rpm, increasing a lot the peak power.

Thanks

Manolis Pattakos