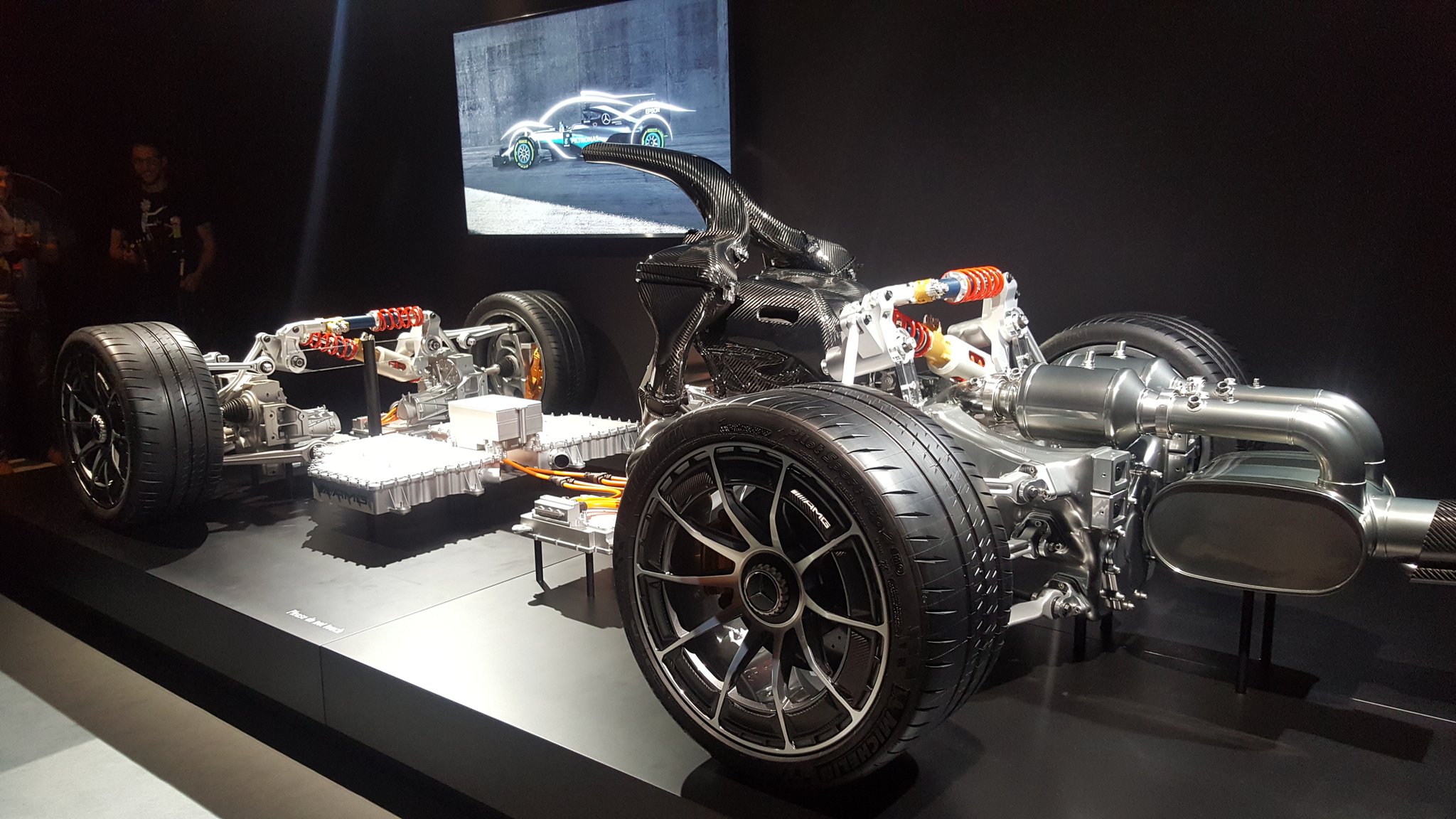

Tobias Moers, the head of AMG, has reaffirmed that Project One will come with a 1.6L turbocharged V6 straight from Formula One, but there will be a few changes to the engine to make it viable in a street-legal super car. For example, the engine's crank will be cast rather than machined. In the name of emissions, the V6's compression ratio will be reduced. And in order to allow the engine to idle at 1,200rpm rather than a race car-like 4,000rpm, AMG will have to rework the fuel injection system. The engine will, however, retain the ability to scream all the way to 11,000rpm.

Unfortunately, the V6 will also keep the racing car's maintenance schedule. That means the engine will have to be totally rebuilt after 50,000km, or just 31,000 miles.

"We have an understanding of about 50,000km," Moers said of the car's engine longevity, according to Motoring. "This OK for us. I think that's good enough."

Still, that shouldn't be much of an issue considering most owners won't be using the Project One as a daily driver. Moreover, anyone with deep enough pockets to afford the $2.4 million Project One in the first place likely won't balk at the price of a full engine rebuild.

In addition to the powertrain details, Moers also confirmed that the Project One will use an automated manual gearbox in place of a dual-clutch unit. Moers cited weight as the reason for going with an automated manual.

The Project One's gas engine will be supplemented by a pair of electric motors at the front axle. Each electric motor will provide about 163 horsepower; total system power will be in the neighborhood of 1,000 horsepower.

AMG is planning on building just 275 units of the Project One. The car will be shown for the first time at this fall's Frankfurt Motor Show. Deliveries should commence by late 2018 or early 2019.

Why does the injection system need rework to be able to idle at a lower speed? Are the injectors not able to open and close fast enough, to allow a short enough duration with the high pressure of these systems? I thhought the camshafts would be the ones who needed redesigning.

And why does the crank need to be cast, rather than machined? Seems you would only do that for cost reasons, but why cheap out in such a car?

And does lowering the combustion ratio reduce emissions? I thought a higher CR gave a more efficient combustion i.e a cleaner combustion?

Source :

http://www.leftlanenews.com/amg-dishes- ... 94916.html