You have an accumulator act as a reservoir to store hydraulic pressure, much like the fuel pump is driven by the engine to create 500bar pressure, you could charge an accumulator with hydraulic pressure from a gear driven by the transmission input shaft or crankshaft or like any other engine ancillary. You would store this hydraulic pressure independent of the ES and release it to directly drive the MGU-K when needed. This system would be completely separate from the ERS system.

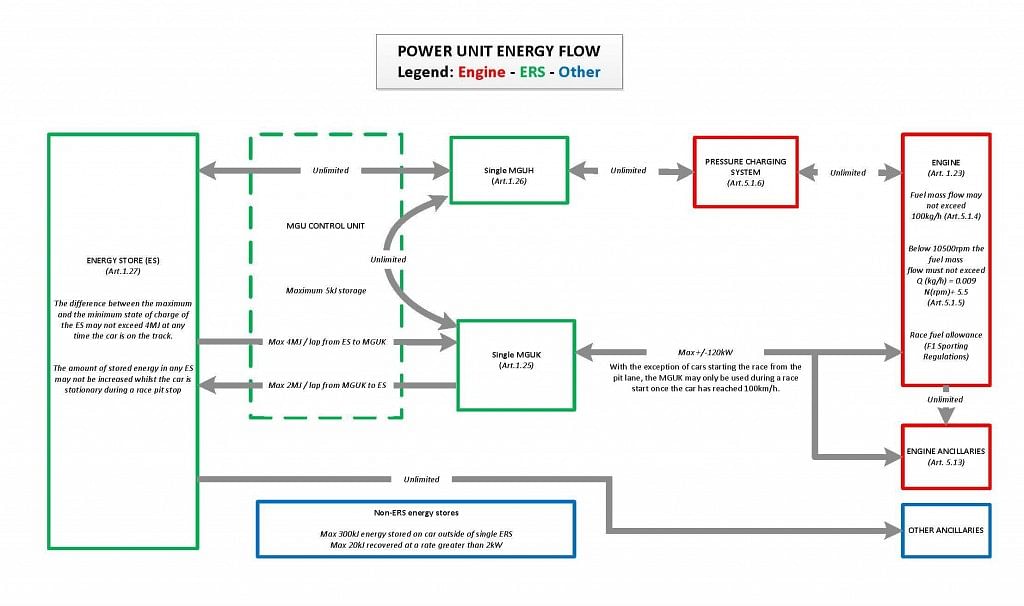

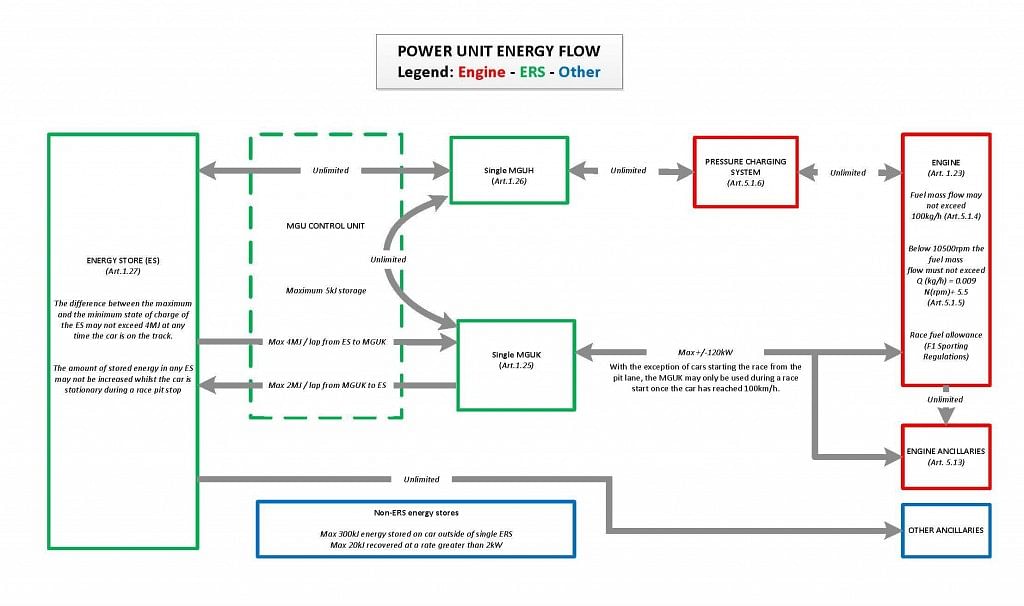

According to the energy flow chart, the engine ancillaries can send power to and from the MGU-K

And any non ERS energy storage can recover up to 300kJ. Or about 2 seconds of extra deployment. Although those 300kJ don't specify if they have the same per lap requirement as the ES to MGU-K

Here are the regulations regarding 5.13

5.13 Engine ancillaries :

All coolant pumps, oil pumps, scavenge pumps, oil/air separators, hydraulic pumps and fuel pumps delivering more than 10bar must be mechanically driven directly from the engine and/or MGU-K with a fixed speed ratio.