Hello all.

This array:

and this plot:

show “relative data”.

TIME:

If the Audi TDi “changes” at 6,000rpm, a “similar” PatOP (or OPRE) would change at 7.800rpm (1.3*6,000rpm).

Why?

Because the PatOP running at 7,800 keeps the piston at the last 15% of its stroke for as long as an Audi Tdi DSG ( running at only 6,000rpm ) keeps its piston at the last 15% of its stroke.

To get an idea what this 15% means for an engine having 16.5:1 compression ratio: while the “actual” expansion ratio for a fuel droplet burnt exactly at the TDC is 16.5:1, for a fuel droplet burnt when the piston is 15% of its stroke away from the TDC the actual expansion ratio is 5.7:1.

The 30% higher (efficient) rev limit of the PatOP means proportionally higher power output.

And because the PatOP is a 2-stroke:

with the same BMEP with the Audi Tdi DSG, the PatOP will make (from the same capacity) 2.6 times more power,

and with only 85% of the BMEP of the Audi Tdi DSG (judging from the marine engines wherein the medium speed 4-strokes run at 25bar MEP while the low speed 2-strokes run at 20+ bar MEP), the PatOP would make “only” 2.2 times the power of the Audi Tdi DSG.

INERTIA:

With half stroke per piston (same “combined” stroke), the acceleration of a PatOP pistons is half than the conventional (at the same revs) and 15% lower when it runs at 30% higher revs than the conventional.

With, say, 110 bars maximum pressure (direct injection turbo diesel), the maximum gas force on each piston of the PatOP prototype engine is 5.5tons (55,000N).

With the 64mm piston stroke of the PatOP prototype (128mm combined stroke), the resulting inertia acceleration at 7,800rpm is 2,700g (27,000m/sec^2).

With 95.5mm combined stroke (47.75mm piston stroke), i.e. as large as the piston stroke of the AUDI Tdi DSG, the maximum acceleration of the piston of the PatOP drops to 2,000g at the 7,800rpm.

Accordingly, the inertia loads in a “similar” PatOP running at 30% higher revs than the conventional Audi Tdi DSG are still way lower than the combustion loads.

FRICTION:

Regarding the mechanical friction: just like the Achates Power, the Junkers Jumo and the Doxford, the PatOP is a 2-stroke engine; and as such it has substantially lower Friction Mean Effective Pressure (FMEP) than a “similar” four stroke Audi Tdi DSG.

DATA:

Has anyone, ever, seen a dyno plot of a motorcycle (say a CRF450 Honda, or other, it doesn’t matter) or of a car engine having the Cross-Bishop rotary valve on the its cylinder head?

Or a “specific fuel consumption” plot?

Or, preferably, a “lube specific consumption” plot?

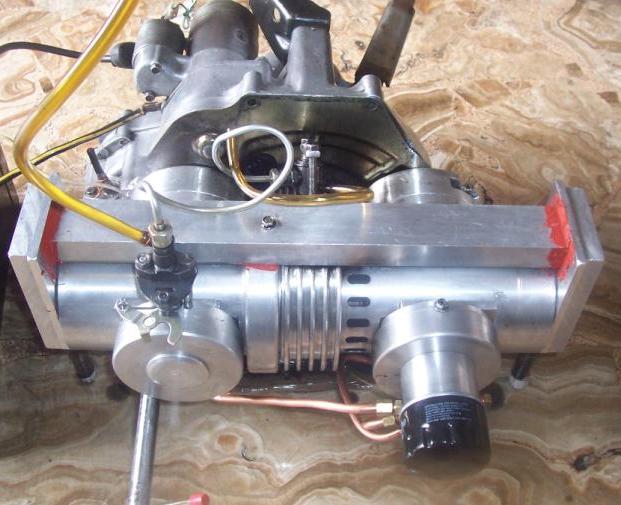

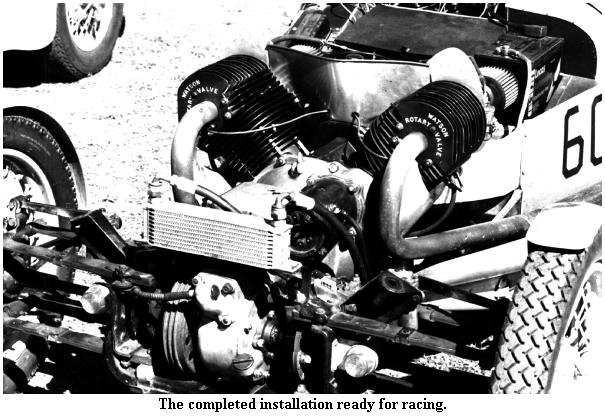

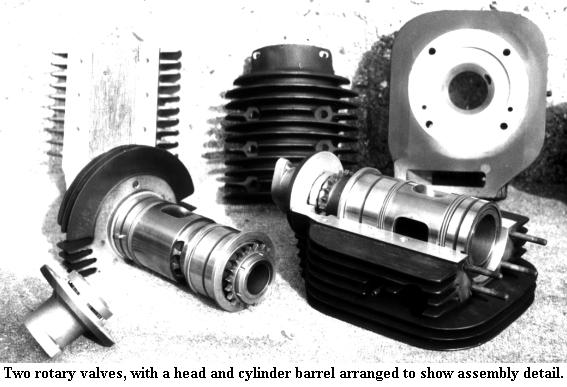

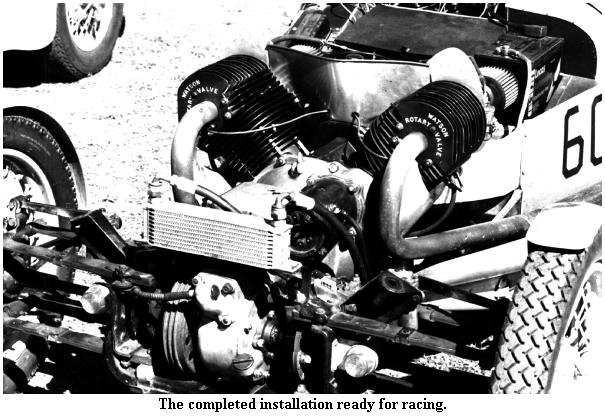

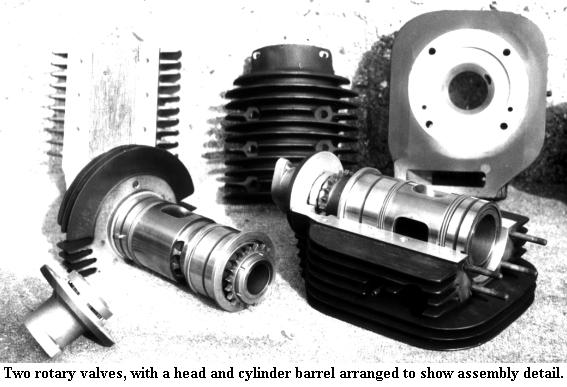

The most relevant info I found in the web is the Ralph Watson rotary valve (quite similar to the Cross and to Bishop rotary valve) mounted on an old V-90 two-cylinder air-cooled engine.

Can someone tell the difference between the Watson and the Bishop rotary valves?

QUOTE from Watson’s article at

http://ralphwatson.scienceontheweb.net/rotary.html

“Oil consumption amounts to less than a litre in 5,000 miles and multi-grade oil has always been used.

When compared with the original much modified poppet valve engine, the rotary valve engine has slightly more power and this results in an extra three m.p.h. top speed. There was a significant increase in low speed torque and this is of considerable advantage, in view of the fact that the car has only a three-speed gearbox. In view of this, I was unwilling to open the valve timing further, at the risk of spoiling the power curve, which exactly suits the car. The rotary valve engine has proved more economical than the original engine and the increase in torque would no doubt account for this.”

End of QUOTE.

Quote from Marc Jackson’s (Muniix) post:

“Where is the cylinder pressure data to confirm this, because this contradicts the published data and experience.

You need to provide evidence to contradict established well understood and evdence based knowledge.”

Thanks

Manolis Pattakos