gruntguru wrote: ↑21 Jun 2017, 08:45

n4rf wrote: ↑21 Jun 2017, 07:58

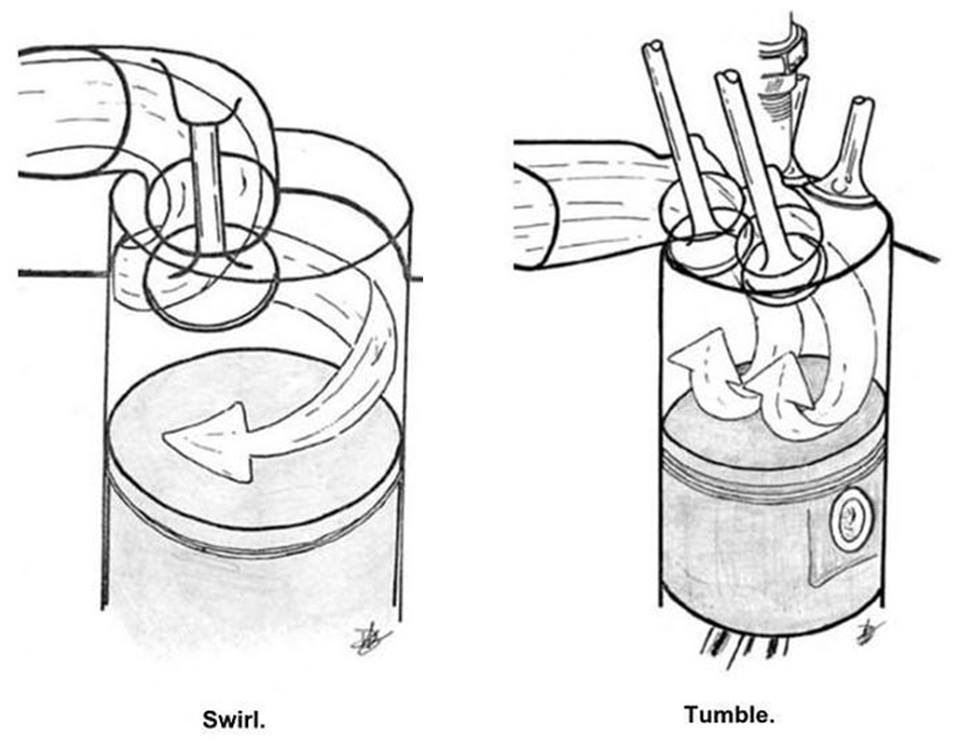

Reason for tumble in TC-GDI is mainly mixture preparation. The tumble motion is most prominent when the piston is close to BDC.

Nice post and pics.

I would think the main reason for tumble replacing swirl is the pent-roof chamber and the difficulty of producing swirl without reducing gas flow.

Tumble tends to extinguish rapidly as TDC is approached - unlike swirl. The "tumble racetrack" becomes a slim rectangle with two long straights. The "swirl racetrack" remains circular (with - in many designs - a reducing diameter which increases velocity. Think diesel with chamber in piston crown.)

The charge motion is not due to the piston or combustion chamber shape, it's rather the other way round. However, the charge motion itself also isn't the root cause for all of this.

The big difference between Diesel (swirl) and Otto (tumble) is, that a Diesel engine needs macroscopic charge motion at/around TDC, because, at least close enough, injection = ignition. So the mixture formation or preparation happens at/around TDC. For an Otto combustion system, the injection happens (mostly) during the suction stroke, thus giving loads of time till ignition. So you need macroscopic charge motion during the suction stroke and at the beginning of the compression stroke. However, for the combustion itself you want microscopic charge motion to increase the burn speed or reduce the burn duration. With that you get closer to isochoric combustion, which is generally beneficial for your thermal efficiency. So you break up the macroscopic tumble motion and end up with microscopic small-scale turbulence (i.e. eddies) with a very high turbulent kinetic energy.

Maybe as a general sidenote: Combustion in piston-engines only works in a range of engine speeds because it is a turbulent combustion. The turbulence increases with engine speed, and with that the turbulent combustion velocity increases. The laminar combustion velocity stays pretty much the same, so with laminar combustion you wouldn't be able to speed up.

With that being clear (hopefully), it is clear, why you want as much turbulence as possible for pure combustion efficiency (isochoric combustion as somewhat ideal). However, you have to balance that with the effort to create this turbulence, as mentioned by someone.

But you can actually give up quite a lot of flow efficiency of the intake ports to achieve more tumble. There are (good) TC engines out there that loose up to 30% of flow coefficient of the intake ports/valves compared to really good NA engines and end up with state-of-the-art efficiencies. You have to design the turbocharger accordingly, obviously.