- Login or Register

No account yet? Sign up

10:30pm @ 297 degrees K, fly QantasTommy Cookers wrote: ↑31 Mar 2018, 14:10...... ok I'll bite - on this cold rainy UK holiday

otoh and fwiw

there was a lot of argument over this about a year ago

the crossplane straight 4 (as invented in Japan decades after the sidecar WC-winning German URS engine)

small differences are possible within this category

iirc what I said last time was that the crank can be smaller diameter and lighter saving eg bearing losses

because the inertia forces are evenly spaced (at the expense of unevenly spaced combustion forces)

and at very high rpm with NA the inertia-related energy is greater than the combustion-related energy

there is/was a Yamaha advert claiming of it giving technomagic effects at the rear tyre

which I have said is false because the tyre is isolated from crankshaft torque perturbations at 10000 rpm

isolated by the elastic etc behaviour of the long load path between crank and road

these technomagic effects seem imo to contradict the earlier fashion of 'big bang' technomagic

Tommy Cookers wrote: ↑30 Mar 2018, 23:28Irving suggested his 'magic' 76 deg crankshaft to the UK makers of 0 deg crankshaft parallel twins - without success

and it would have given little relief from primary frequency vibration

more recently historic race UK machines have had eg 90 deg or 180 deg made from (3 piece bolt-up) Norton crankshaft bits

I suggested here that 135 - 150 deg would be better

50ish years ago BSA/Triumph started making 3 cylinder 750cc machines with 120 deg 1 piece crankshafts

while still making 'old hat' and very vibratory 0 deg 500cc and 650cc twin cylinder machines

the 3s boosted credibility, seeming new and exciting and performing well and with much reduced vibration

they could have used the 3 cylinder as a basis for simple and cheap improved twin

this could be confirmed now ie by cutting down a 3

the 3 has a 3 piece 'salami- style' crankcase (the twin would use 2 of these)

the 3's crankshaft and camshafts etc would be cut down

(the crankshaft could have 3 mains/4 crankcase pieces or 2 mains/2 pieces stiffening added to redundant journal)

a relevant exercise in industrial archaeology- and easier than alternatives

with the 120 deg crank the primary and secondary vibration would be half (the then-existing 500cc twin's)

it would have slung less oil

the machine's sound would have been new and related to the 3 and so better imagewise

a better proposition than Irving's

At the risk of being racially something or other, I would comment that the German cast iron alloys seemed to be much better, from machining and testing (piston, rod etc) for, of all things, a Lanz Bulldog motor!J.A.W. wrote: ↑31 Mar 2018, 15:22Tommy Cookers wrote: ↑30 Mar 2018, 23:28Irving suggested his 'magic' 76 deg crankshaft to the UK makers of 0 deg crankshaft parallel twins - without success

and it would have given little relief from primary frequency vibration

more recently historic race UK machines have had eg 90 deg or 180 deg made from (3 piece bolt-up) Norton crankshaft bits

I suggested here that 135 - 150 deg would be better

50ish years ago BSA/Triumph started making 3 cylinder 750cc machines with 120 deg 1 piece crankshafts

while still making 'old hat' and very vibratory 0 deg 500cc and 650cc twin cylinder machines

the 3s boosted credibility, seeming new and exciting and performing well and with much reduced vibration

they could have used the 3 cylinder as a basis for simple and cheap improved twin

this could be confirmed now ie by cutting down a 3

the 3 has a 3 piece 'salami- style' crankcase (the twin would use 2 of these)

the 3's crankshaft and camshafts etc would be cut down

(the crankshaft could have 3 mains/4 crankcase pieces or 2 mains/2 pieces stiffening added to redundant journal)

a relevant exercise in industrial archaeology- and easier than alternatives

with the 120 deg crank the primary and secondary vibration would be half (the then-existing 500cc twin's)

it would have slung less oil

the machine's sound would have been new and related to the 3 and so better imagewise

a better proposition than Irving's

If I might suggest a more practicable alternative as a 'proof of concept' exercise T-C,

perhaps a pair of cylinders sliced from a junkyard M104 (DOHC 4V) Mercedes-Benz inline six?

That would provide a 1 litre twin, and likely - it could prove it better than the Norton-Cosworth..

& on the Norton 'bolt-up' cranks, poor old Norton didn't have the metallurgical-working facilities to make them

in one piece ( BSA had a long history of gun making, the triple cyl cranks were forged, then twisted to 120 degrees).

But staying with a cast FE centre/flywheel proved too much in racing duty, when the 2 mainbearing cranks got 'ropy',

with the resultant flex fracturing the brittle 'stove material', & ejecting the frangible remains through the cases..

Laverda too, had limited crank making facilities, so as an expedient, made their triples in 180 degree form,

(which made them sound like a 4 with a 'dead pot', to my ear), until the later series went to a regular 120..

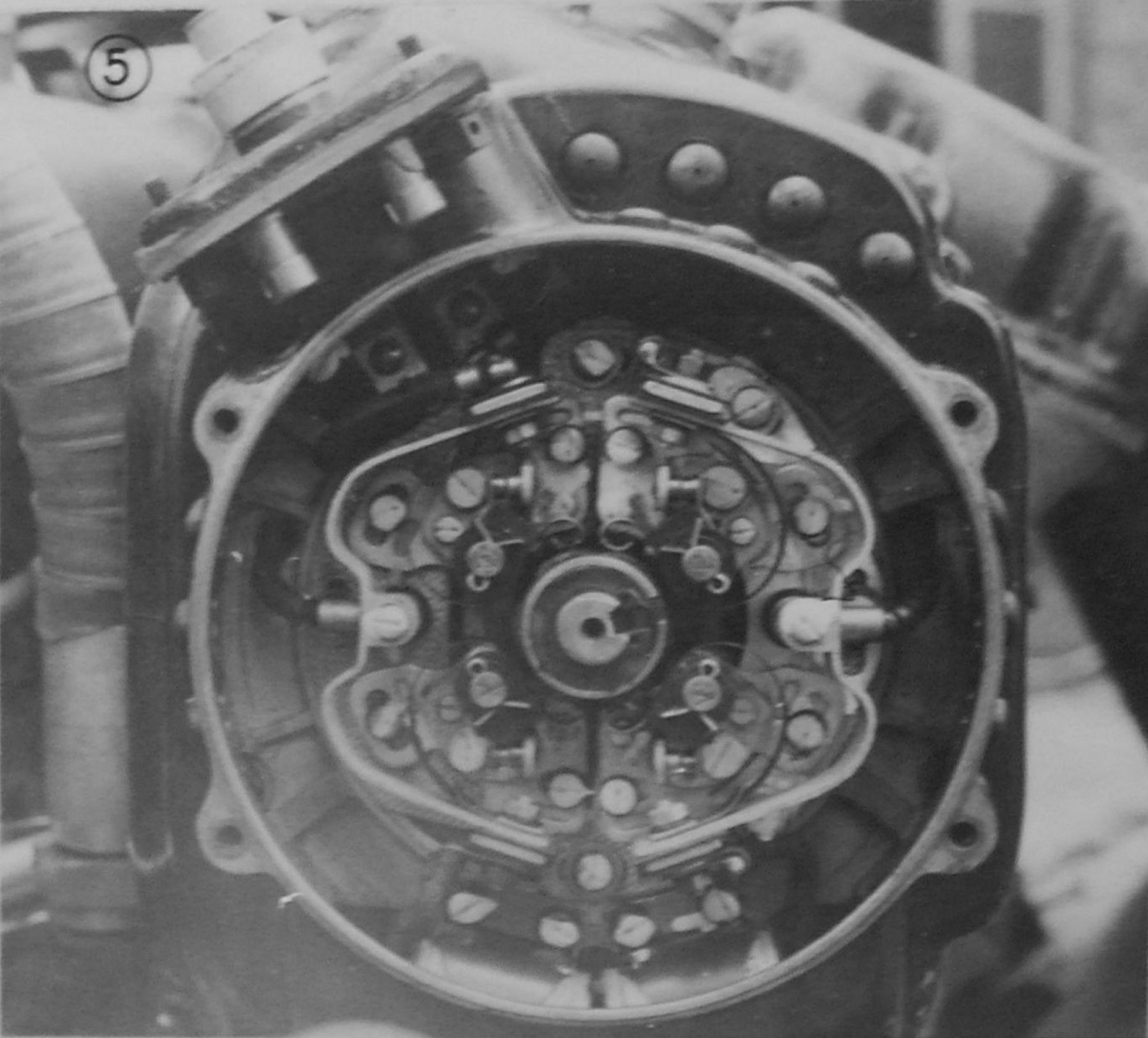

this will cost me a dayJ.A.W. wrote: ↑13 Apr 2018, 10:15Ok engine-tech brainiacs.. guess what crankshaft configuration was used by the Junkers Jumo 222,

a 24 cyl WW 2 German aero-engine which did get off the drawings & in to metal,(to the ~200 engine mark!),

- but never made service..

Anyhow this lump was deemed a 'radialine' being a multiple of inline 4's disposed radially in six banks..

- if you can visualise the Napier Lion, which featured 3 X 4, & double it - so its six-pointed star-like, or asterisk-wise..

Right then, are ya still with me?

Then its anti-climax time.. the Jumo 222 used a basic 180 degree/flat-plane 4-throw crank..

Now as to its bloody firing pattern.. nah.. it gets my neurones grinding, later maybe..

So 6 rods per crank journal? So each bank was 60 degrees apart? That would make for an interesting firing pattern. You could definitely have 3 cylinders fire simultaneously. What a nutty engine, I like it.J.A.W. wrote: ↑13 Apr 2018, 10:15Ok engine-tech brainiacs.. guess what crankshaft configuration was used by the Junkers Jumo 222,

a 24 cyl WW 2 German aero-engine which did get off the drawings & in to metal,(to the ~200 engine mark!),

- but never made service..

Anyhow this lump was deemed a 'radialine' being a multiple of inline 4's disposed radially in six banks..

- if you can visualise the Napier Lion, which featured 3 X 4, & double it - so its six-pointed star-like, or asterisk-wise..

Right then, are ya still with me?

Then its anti-climax time.. the Jumo 222 used a basic 180 degree/flat-plane 4-throw crank..

Now as to its bloody firing pattern.. nah.. it gets my neurones grinding, later maybe..

My first thoughts were with 6 lobes it might be firing a bank at a time, but that would have invented the rocking couple!godlameroso wrote: ↑13 Apr 2018, 23:45So 6 rods per crank journal? So each bank was 60 degrees apart? That would make for an interesting firing pattern. You could definitely have 3 cylinders fire simultaneously. What a nutty engine, I like it.J.A.W. wrote: ↑13 Apr 2018, 10:15Ok engine-tech brainiacs.. guess what crankshaft configuration was used by the Junkers Jumo 222,

a 24 cyl WW 2 German aero-engine which did get off the drawings & in to metal,(to the ~200 engine mark!),

- but never made service..

Anyhow this lump was deemed a 'radialine' being a multiple of inline 4's disposed radially in six banks..

- if you can visualise the Napier Lion, which featured 3 X 4, & double it - so its six-pointed star-like, or asterisk-wise..

Right then, are ya still with me?

Then its anti-climax time.. the Jumo 222 used a basic 180 degree/flat-plane 4-throw crank..

Now as to its bloody firing pattern.. nah.. it gets my neurones grinding, later maybe..