Hey look, I'm just throwing a theory out there. I am aware I could be extremely wrong and as such I don't have every answer to more in depth questions in what im suggesting, but it's great to discuss.Jaisonas wrote: ↑05 Mar 2020, 10:13This is a nice idea and all, but i dont think it can work in the split turbo design. If you were to clutch out the MGU-H, considering it sits between the turbo, you would disconnect the turbine from the compressor, basically shutting the turbo off. You would need a big-ass flywheel to maintain any momentum to the turbine when you were gonna clutch the compressor back in.GhostF1 wrote: ↑05 Mar 2020, 02:01Had another random idea.

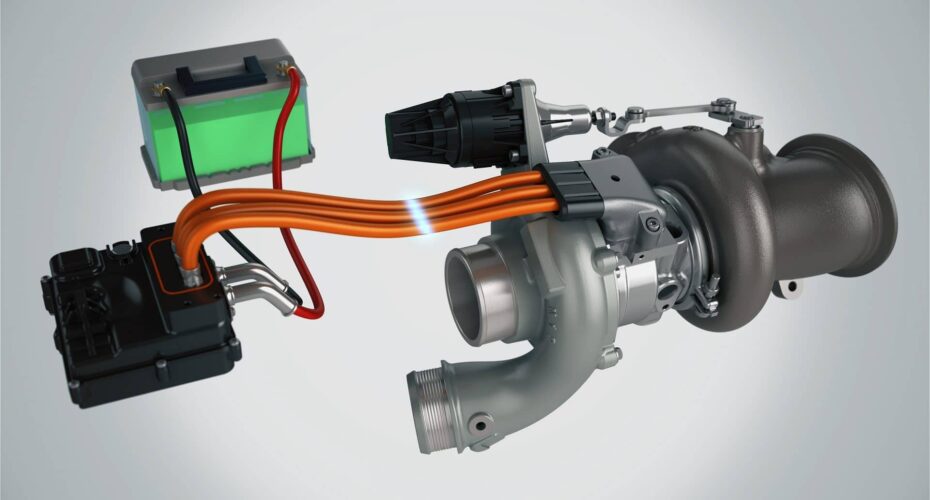

A while ago we were debating whether or not Honda had a clutch between the MGU-H and turbo (brought on by their class of the field performances at high altitude tracks) this is allowed by the regulations, we had decent reasons for both sides (complexity was one, even Renault said they wouldn't due to complexity), I still believe it's likely Honda do, even more so now with the onset of this anti-lag discussion. My main reason for believing in this clutch idea was the theoretical gain in compressor speed it allows. The turbo is not speed restricted but the MGU-H is restricted to 125,000rpm by the regulations, these two have to be geared 1:1 as well so it poses a hard limit on the turbo speed therefore maximum boost potential. So there was an argument Honda could decouple the MGU-H from the turbo at maximum power on straights to allow for an increase in turbine speed to compensate for the altitude deficit, it would also make sense as it seemed evident they may have gotten the mapping a little off sometimes, hence Max's mentioning of turbo lag out of some corners on occasion last year, that was the theory.

So now I am thinking.. why is this anti-lag sound/behaviour most prevalent during high power/quali laps since late last year and not really anything less than that (during sustained race modes, it is not present)? We are talking about it like it's primary use would be for energy recovery benefits and while it is possible, what I'm thinking, mainly because it's most obvious on fast laps, is what if this anti-lag is being used on high power modes as Honda have decoupled the MGU-H and are therefore free to run the turbo at as high an RPM as they want, no longer restricted to the 125,000rpm limit of the MGU-H. This anti-lag is a system which has become available to Honda with skip-fire use so are they using this to compensate for MGU-H motoring loss to sustain the turbo? Or is it to keep the turbine at a certain speed to recouple the H momentarily for power out of corners? Or would that even still be necessary if this is mapped correctly? Or a myriad of other things.

The work with Honda Jet, a lot of focus has been around the turbo from Honda, it's what they bring up all the time. I can't initially see why this is not a possibility for high power modes with the right engine and the right fuel allowing such high boost. Spec 4 and the special new fuel anyone?

As for disconnecting the MGU-H, I can think of a few ideas design wise that would allow the MGU-H to "de-couple" from the shaft which would run straight through without affecting either component of the turbocharger (i.e a really basic explanation, a mechanism where the H can "let go" of the shaft running through it and grab hold again when in operation). So it could be possible. It definitely isn't impossible.

There is more to the operation of each system we need to consider, the timing is a crucial one and the fact it is always Qualifying simulations or the like that this operation is most prevalent, leads me personally to find other explanations. For example if this behaviour was only evident during sustained race mode runs at lower power settings and absent for quali or higher power modes, then I'd be certain the anti-lag sound was for H generation only, but it's quite the opposite.

Whatever this is, it stimulates fascinating conversation!