strad wrote: ↑21 Jul 2020, 22:03

When drag racing we often used the lightest pistons and had to watch out for the ring lands being pounded shut.

In the posted pictures I find the top of the shown piston interesting. How does that surface interface with flame propagation?

Ring lands being pounded shut sounds like a detonation problem.

Most top natural aspirated drag racers (Pro Stock, Comp, etc.) and NASCAR, all contend with minimum weights by rules, but they will sacrifice a few grams of weight for a stronger part. Ring seal is the whole world to them and they all found with light pins / pistons, they would lose some. Consider NASCAR engines are only have ~.1% blowby, even after 700 miles or so, and that is pretty impressive. Strong compact graphite iron blocks help, and they're running 948mb of crankcase vacuum to get the low tension .5mm rings to seal.

Most top guys will tell you, light weight at the expense of strength was very 1990s / early 2000s thinking.

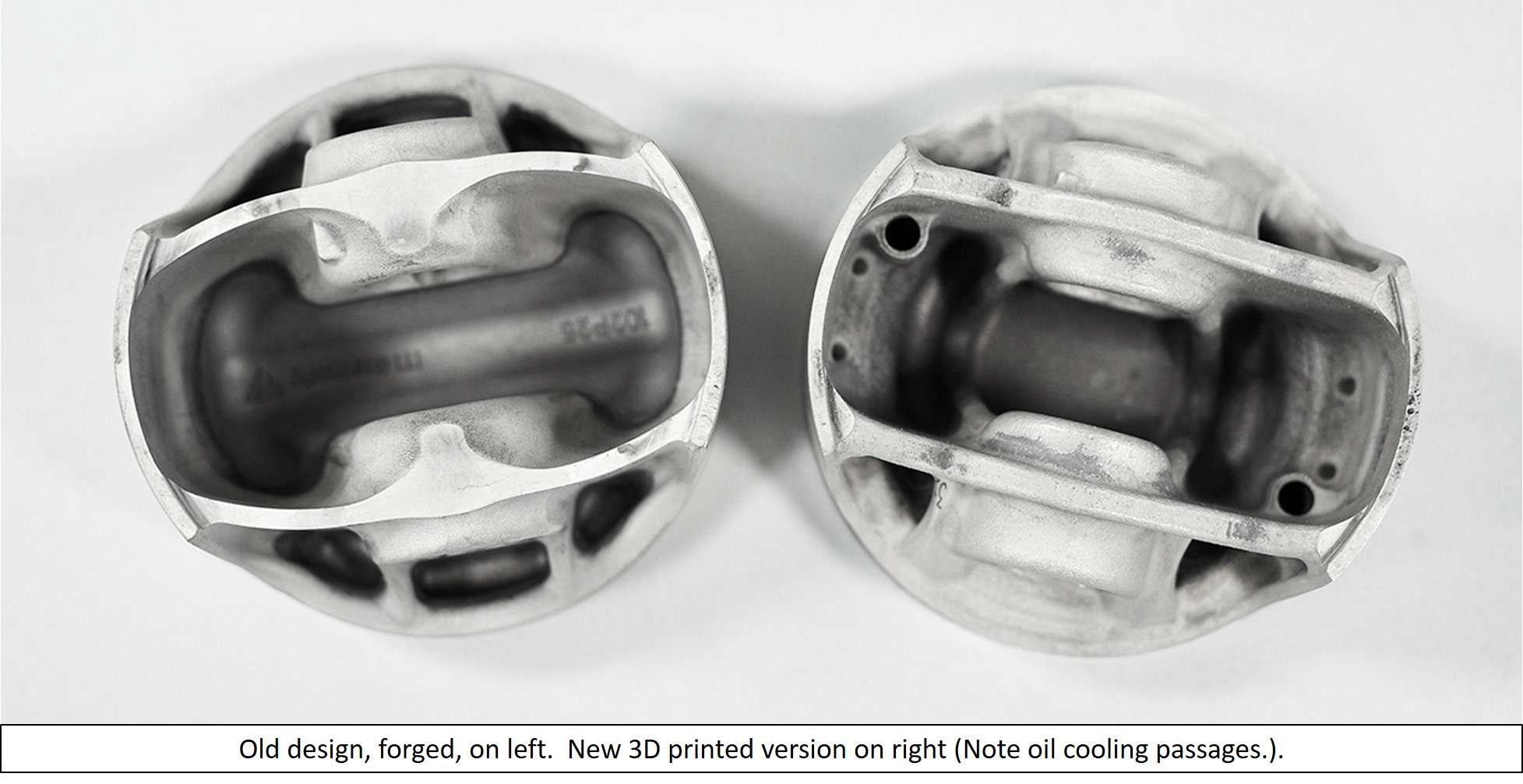

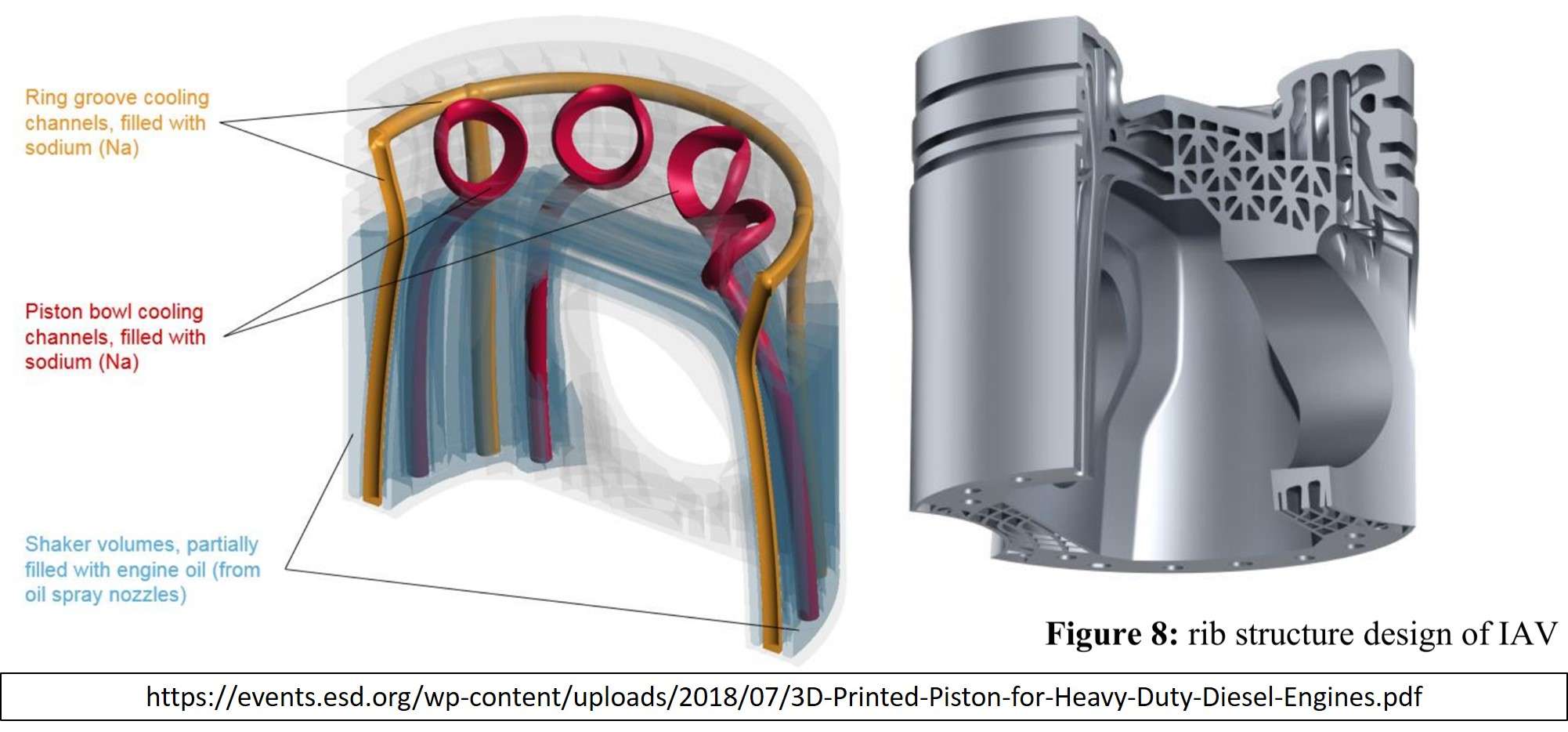

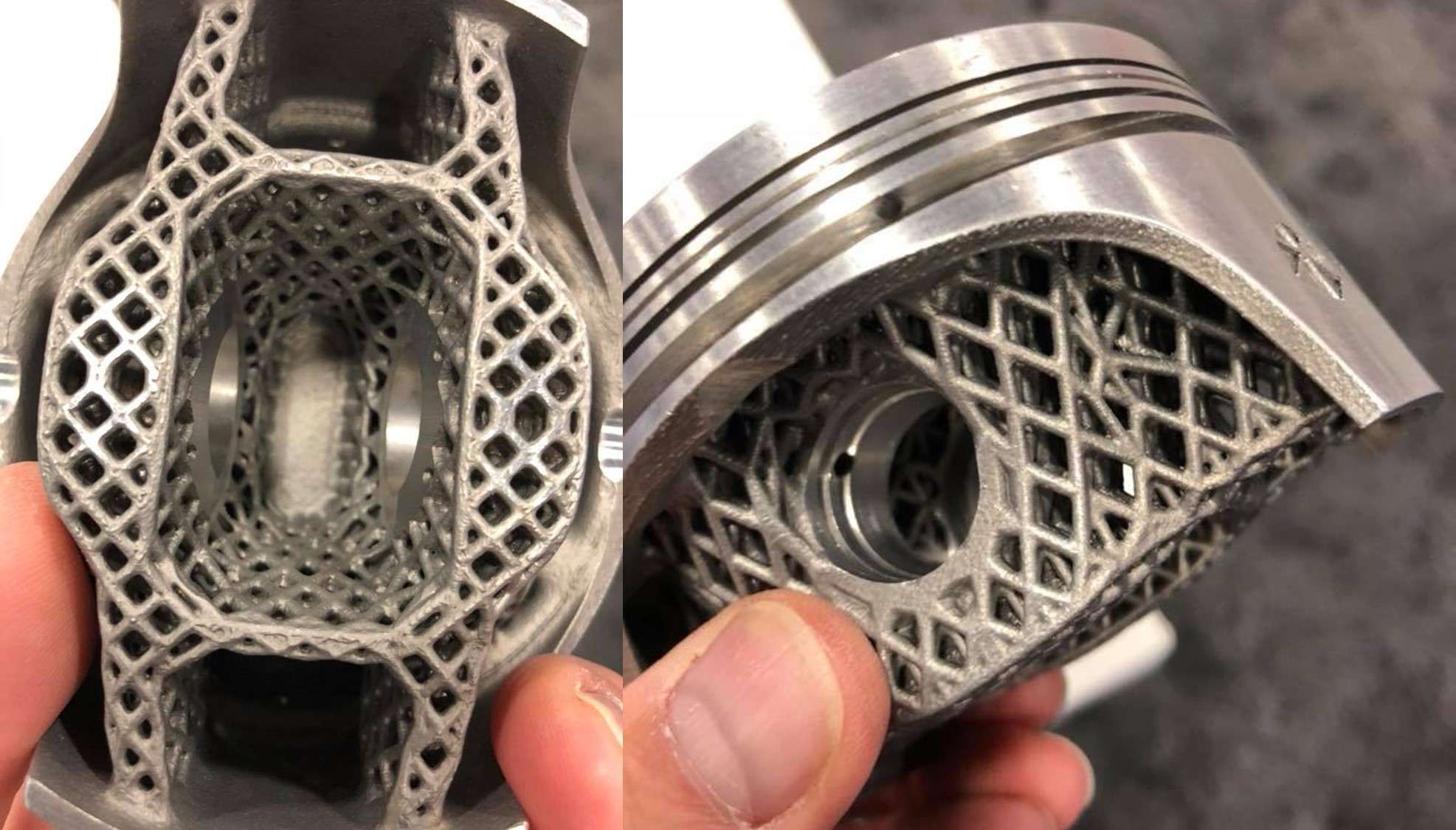

If 3D printing allows lighter pistons, but to be as strong as they are, then I think there is a chance you'll see them gain wider exceptance in classes that don't mandate minimum weight. There might be some advantages in the cooling channels as well that can't be machined in traditionally. NASCAR and the like aren't limited by piston cooling, but ultimately by peak cylinder pressure for the duty cycles needed from the rotating assembly. Drag racers could care less as they can just put more fuel through it or their run / rebuild times are so frequent.