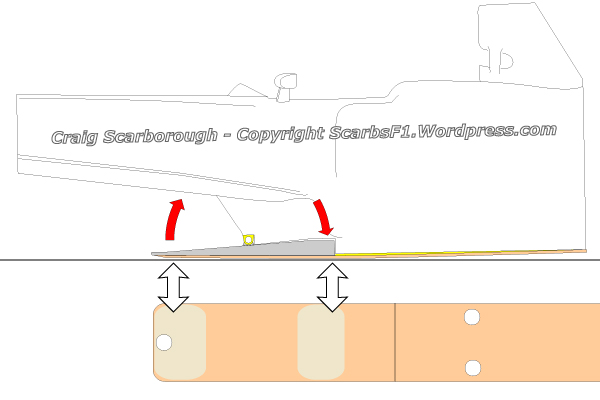

I am not not seeing any mechanism here. I am seeing a rigid 1 piece carbon floor.

Which is mated to a rigid plank held down by high strenght bolts.

There is no pivot. It's a cantilever.

Also one error in this diagram is that it doesn't take into account the whole body of the car.

That pivot cannot be assumed to be stationary. The real pivot would be the rear wheel center line.

This point will only act as a pivot if the forces on the front axle are greater than the force acting at the tip of the splitter.

All moments acting on the car taken about the rear wheel center line are to be greater than the clokwise moment required to bend the 1 piece CFRP about that pivot point.

So if we know how much force it takes a 1 piece floor bonded to the plank by the suspected deflection point and we compare to the total force on the car we can know if the idea feasible.

In leymans terms if i nail a metal ruler to a table i have to include the weight of the table and use the table's rear legs as the pivot point, not the nail.

Only if the weight of the table is far greater than the force to have deflection in the ruler do i ignore it, as it wont have any significant motion compared to the ruler.

If the ruler is so stiff that the moment applied to it surpasses the moment of the table's weight about the rear legs, the table will lift before we see any deflection in the ruler about the nail (the nail being the other pivot point).

So the deflection force at the splitter, and thus the strength of the cfrp and plank have to be really small compared to the other external forces on the car.

Numbers have to come into play to analyse this idea. It may not be statically determinate either.

So are the aero loads and their moments stronger than that moment at the splitter?