A little mid-thread reminder that the content of this thread is essentially a shortened version of the content of the book “Classic Racing Engines” by Karl Ludvigsen:

http://www.bentleypublishers.com/automo ... tents.html

https://www.amazon.co.uk/Classic-Racing ... +Ludvigsen

Further explanation in the first post of the thread:

viewtopic.php?p=805009#p805009

******************************************************************

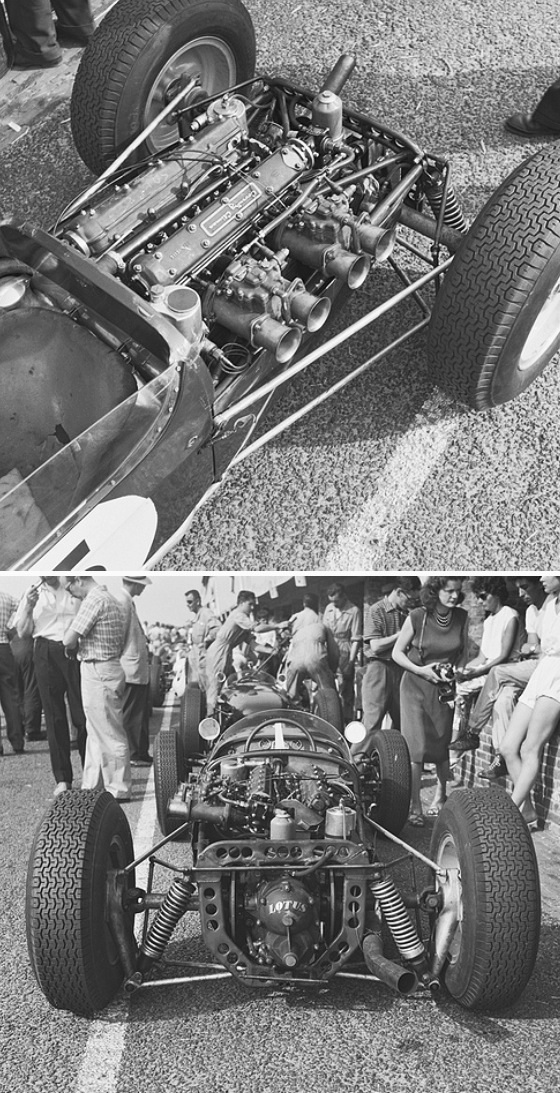

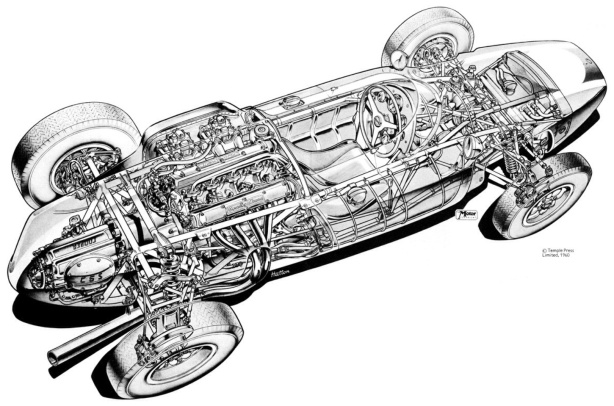

1960 Coventry Climax FPF 2.5-litre four

1960 Coventry Climax FPF 2.5-litre four: A robust design cylinder block which like the cylinder head was cast by Birmal of RR50 aluminum alloy, the barrel shaped crankcase extended down 89mm bellow crankshaft centerline, was finned along the sides, a shallow light alloy finned sump closed the bottom.

Cylinder liners were pinched at top of block and sealed by laminated cooper rings, liners were a close fit at bottom of water jacket and sealed by O-rings. 10 main studs attached the head with 4 additional studs on the exhaust side were water flowed from the block to head.

Steel main bearing caps with 2 bolts + being cross-bolted to sides of block. Oil pump carrier was also bolted across the 3 center main bearing caps for added bottom-end stiffness. Forged I-section EN24 steel con-rods with caps retained by half-inch bolts were used. All bearings were thin-wall indium-plated lead bronze.

A forged steel crankshaft with 4 recessed and bolted on counterweights, having the big-end journals internally bored and being part of an end-to-end network of oil drillings which extended into the 4 counterweights. Dry sump by 2 scavenge pumps and 1 pressure pump. Connections for oil to the oil tank was with pressure pump intake being on the left side of the block and 2 scavenge pump outlets being on the right side of the block.

Driven from ball-bearinged spur-gear train at front of engine, the centrifugal water pump was mounted low at front. Bronze valve guides were used, the exhaust guides being finned and in direct contact with cooling water. Valve-seat inserts were shrunk-into the head. Head porting advice from Harry Weslake was sought. 1 14mm-spark plug per cylinder was used. Valves at an included angle of 66 degrees, with inlets at 32 degrees and exhaust at 34 degrees were used.

Domed cast aluminum full skirt pistons were made by Brico, they had 2 Dykes-type compression rings and 1 oil ring. High-nickel Nimonic 80 steel valves were used, separate magnesium tapped blocks with inserted iron guides for inverted flat topped chilled cast-iron tappets surrounding 2 valve coil springs were used. 2 Weber 50DCO3 twin throat carburetors were used.

Specifications:

Cylinders l4.

Bore 94mm.

Stroke 89.9mm.

Stroke/bore ratio 0.96:1.

Capacity 2496cc.

Compression ratio 11.9:1.

Con-rod length 129.5mm.

Rod/crank radius ratio 2.9:1.

Main bearing journal 63.5mm.

Rod journal 54mm.

Inlet valve 49.2mm.

Exhaust valve 42.8mm.

Valve lift 10.4mm.

Timing duration 290 degrees.

Valve overlap 90 degrees.

Inlet pressure 1Atm.

Engine weight 132kg.

Peak power 240BHP@6750RPM.

Piston speed corrected 20.4m/s.

Peak torque 287Nm@5000RPM.

Peak BMEP 210PSI.

96.2BHPper litre. 0.55kg per BHP.